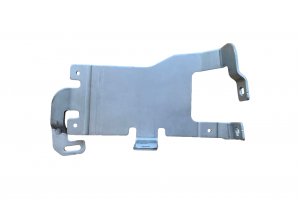

Automotive Front Child Part

Brief Description: 3D printer

Part Name: Automotive Front Child Part

Material Grade: Material AL5-STD -TZ-UE

Material Size: Material size is 3.00mm x 798mm x 177mm

Process: 800T Progressive

Cavity: Tool cavity is Right and Left two Parts Out

Part Feature and 3D printing in Automotive Industry

This is a very simple product, no complex shape, no special tolerance demand, no quality difficulty. With the development of 3D printing, we promoted to produce this part.

What is 3D printing?

3D printing, also known as additive manufacturing, it is a process of making three dimensional solid physical products and parts from a digital file in different materials.

Compared with traditional manufacturing, milling, grinding or CNC methods, 3D printing enables you to produce complex shapes using less material.

3D printing is used in all most all industries you could imagine.

Automotive manufacturers and suppliers have been utilizing 3D printing for a long time. They are printing spare and replacement parts, tools, jigs and fixtures but also end-use parts. 3D printing helps to reduce high risk of stock, shorten lead time for design and manufacturing. For those parts that were out of production, small demands and non-consumable for decades, then 3D printing to be used all over the world.

3D printing is changing automotive manufacture industry.

Even though, currently 3D printing is unable to print a full vehicle, but with the development and improvement of the process and materials, it should be a possible.

3D printing benefits for automotive manufacturing:

˜Material efficiency

As the 3D printing process producing the product layer by layer, which could use material only in needed areas, compared with traditional methods, the material could be controlled better and less waste.

And 3D printable material range is constantly expanding. More and more materials will be used in 3D printing.

˜Shorten lead time

Normally automotive products are produced by tool and dies, from the designing to assembling to final production, at least 2 months. However, 3D printing could finish in a short time.

˜Cost reduction

For small annual demand products, a tool is not best choice, usually by prototype.

With 3D printing population, prototype die is also not best choice.

If you have interest in 3D printing for automotive parts, dies, jigs and fixtures, please contact with us.